Hope mechanism presentation

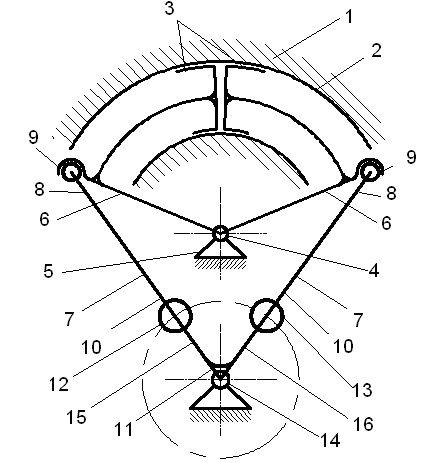

This concept uses mostly the same elements as a conventional engine (four-stroke or two-stroke) configured in an innovative arrangement and shape. It has a toroidal cylinder 1 where work two toroidal pistons 2. Each toroidal piston 2 has few components, respectively the compression portion (toroidal crown portion) 3 where are mounted the rings and some rocker arms 4, fixed on the piston 2, which make the connection with a central joint 5 located in the torus center. On the arm 4 is fixed a bolt 6 which acts the connecting rod 7. The connecting rods 7 can link the toroidal pistons 2 with at least a crankshaft 8. If it has two crankshafts 8, they are connected using two gears 9 with equal diameter (1:1 ratio) to have same rotation speed. The toroidal pistons 2 work suspended in the central joint 5 and will be no contact between them and the toroidal cylinder 1 or the contact has insignificant friction. Only the rings are in forced contact with the toroidal cylinder 1 to ensure the sealing of the combustion chamber 10. The rings are similar with these used by the classic engine. In fact this mechanism eliminates the normal force exercised on the cylinder. The combustion chamber 10 with variable volume is included between the two toroidal pistons 2 and the toroidal cylinder 1.

Double crankshaft mechanism

There is also a variant with a single crankshaft.

Single crankshaft mechanism

A physical model of this mechanism was build to demonstrate few of its advantages.

HOPE Mechanism physical model

Examining this prototype can be see a constant distance between the toroidal pistons and the toroidal cylinder when operates. Even the mechanism is achieved from polycarbonate, we can easily fill, when rotate manually the mechanism, a very low friction, the mechanism being acted with minimal effort.