State of the art

Historically, the opposed-piston engine set combined records for fuel efficiency and power density that have yet to be met by any other engine type. The fundamental thermal efficiency benefits of this engine type along with its low emissions, small package size and weight, and low cost relative to current engines make it an attractive alternative for future commercial and passenger vehicles. The precursor of this concept was the Junkers Jumo 207 Diesel Engine.

Opposite piston Engine: Unmatched combination of Fuel Efficiency and Power Density

http://en.wikipedia.org/wiki/File:Opposite_piston_engine_anim.gif

Animated sectional view of an opposite piston engine / Animierte Schnittansicht eines Gegenkolbenmotors Source: self-made UtzOnBike with Autodesk Inventor {{GFDL}} Category:GFDL

Some companies already developed concepts which present high power density. It is the case of the OPOC (opposed piston opposed cylinder) engine presented by Ecomotors with FEV.

OPOC - Ecomotors

It comprises two opposing cylinders per module, with a crankshaft between them, each cylinder having two pistons moving in opposite directions. This innovative design configuration eliminates the cylinder-head and valve-train components of conventional engines, offering an efficient and simple core engine structure. The result is an engine family that is lighter, more efficient and economical, with lower exhaust emissions. The big advantages of this concept are the power density which is around 2 kW/kg and the effective efficiency which is at least 37% in real proved conditions. The disadvantages are:

- It is not adapted for automotive application, the external volume of the engine being developed into a single direction;

- The scavenging of the cylinder is made by an external compressor, electrically acted, which present an important cost;

- It is deigned as a single unit with two cylinders and to have more than that (4, 6 or 8) is very complicate;

- Not four-stroke solution proposed.

Another configuration was made by Achates Power.

Achates Power Diesel engine

It comprises two opposing pistons per module, with two lateral crankshafts, each cylinder having two pistons moving in opposite directions. This innovative design configuration also eliminates the cylinder-head and valve-train components of conventional engines. In conjunction with the thermal efficiency advantage inherent to opposed-piston engines, this concept realizes significant reductions in fuel consumption over conventional four-stroke compression ignition engines. The disadvantages are:

- The scavenging of the cylinder is made by an external compressor, electrically acted, which present an important cost.

- It has a complex construction.

- Not four-stroke solution planned.

Another solution was proposed by me few years ago to achieve the simplest powerplant for hybrid vehicle: the two-stroke solid piston engine.

Two-stroke solid piston engine

It is represented by a kind of “free piston engine” with crank mechanism. Having only three main parts in motion for each two opposed power cylinders it represents the simplest engine with reciprocating piston. Despite the simplicity, this arrangement contains two compressors included in the volume of the engine which supply with fresh air the combustion chambers. The advantages of this engine are the high power density, the simplicity of the concept, the lubrication similar with four stroke engine and the fact that the part of piston which works in the combustion chamber is suspended (it is no friction with the combustion chamber walls). Unfortunately the two cylinders engine works unbalanced. To have a balanced engine is possible only with two rows of cylinders (four cylinders) or more.

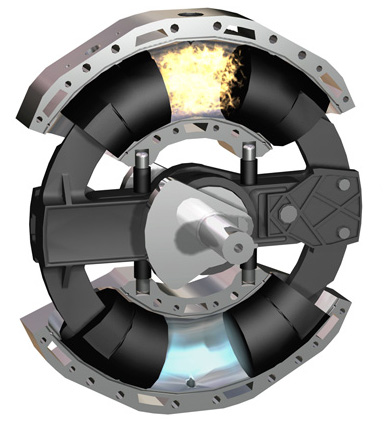

Some toroidal engine with opposed piston were also proposed: Tropo engine and Niama-Reisser engine.

TROPO engine (Devaere Engineering)

Niama-Reisser engine

Although very compact, these engines have a high thermal stress, which can affect the durability and the performance. A common denominator of all these solutions is the need to use an electric compressor to achieve the scavenging. Such a compressor is not yet validated in practice by an existent series product. Therefore if the electric compressor fails the engine itself does not work. On the other hand they can use external superchargers (Root, screw or vane types), which are very complex (around 80 additional components each) and expensive.

In the last period (2012) the toroidal engines begin to become very interesting at least for the automotive manufacturers. A major innovation competition, organized by a big innovation German agency named NOAE, was gained by the toroidal engine developed by a Suisse company. The jury was formed by specialists from Volkswagen, Renault, Bosch, Audi, Ford, Magna and others. The inventor is Herbert Huettlin.

Huettlin engine

Despite the award, also this engine has few disadvantages:

- It uses a cam mechanism to transform the oscillating motion in rotation motion which limits the rotation speed at 3000 RPM.

- The cams are difficult to be manufactured.

- The stroke of the piston is relatively short (not extended expansion stroke).

- More than two cylinders are difficult to be achieved.

- The power density is relatively low.

Another example is the oscillating piston two-stroke engine imagined by Richard James. This is very close as mechanism with my concept. This engine type uses the volume behind the pistons as a pump for scavenging process. This pump is highly inefficient because of the big death volume, affecting very much the volumetric efficiency. When experimented this engine, Richard James used rectangular section pistons having linear rings pushed against the combustion chamber walls by some spring expanders (like in Wankel case). It is a very defective sealing system of the combustion chamber. The lubrication of this engine is made by the mixture of oil and fuel, producing a big pollution. On the other hand it is not proposed a four stroke variant.

![Richard James engine [Bill Todd animation]](http://www.hybrid-engine-hope.com/media/pagini/72_2bcafb6ee26dcfe6b82c67a7d7128db2.gif)

Richard James engine [Bill Todd animation]

Another example with toroidal pistons is Taurozzi engine. Even it is a four stroke solution, this concept is relatively complicate having two cylinder heads. Also the heat loses are important and consequently the efficiency is diminished.

Taurozzi engine

An Argentian company Tausem produces in series a pendulum compressor. This demonstrates that the technology to achieve well finished toroidal cylinders is existent in practice.

Tausem toroidal compressor